| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : DINGSCO

Model Number : According to customers' requirements

Certification : ISO 9001:2015,PED 2014/68/EU,API 6A,API-20B,TSG,NORSOK

Place of Origin : China

MOQ : Negotiable

Price : Negotiable

Payment Terms : T/T

Supply Ability : Negotiable

Delivery Time : (Sample order) 7 days

Packaging Details : According to customers' requests

Product Name : Nickel Alloy Forging Bar Incoloy Alloy 925 UNS N09925

Size : Customized

Application : Construction,Bridges,Petrochemical Industry,Ship Building,Engineering General Structural Purposes,Offshore and Onshore Services

Material : Nickel Alloy Incoloy 925

Type : Forging Bar

DIN : W.Nr:2.4858

UNS : N09925

Melting Range : 1311-1366°C

Nickel Alloy Forging Bar Incoloy Alloy 925 UNS N09925 High Tensile Fatigue Strength

INCOLOY alloy 925 (UNS N09925) is an agehardenable nickel-iron-chromium alloy with additions of molybdenum, copper, titanium and aluminum. The alloy’s chemical composition, listed in below, is designed to provide a combination of high strength and

excellent corrosion resistance. The nickel content is sufficient for protection against chloride-ion stresscorrosion cracking. The nickel, in conjunction with the molybdenum and copper, also gives outstanding resistance to reducing chemicals. The molybdenum aids

resistance to pitting and crevice corrosion. The alloy’s chromium content provides resistance to oxidizing environments. The titanium and aluminum additions cause a strengthening reaction during heat treatment.

INCOLOY alloy 925 is used in various applications requiring a combination of high strength and corrosion resistance. Because of the alloy’s

resistance to sulfide stress cracking and stress-corrosion cracking in “sour” (H2S containing) crude oil and natural gas, it is used for down-hole and surface gaswell components including tubular products, valves, hangers, landing nipples, tool joints and packers. The alloy is also useful for fasteners, marine and pump shafting and high-strength piping systems.

Common Trade Names:

lncoloy 925, Alloy 925, UNS: N09925, NCF 925, W. Nr: 2.4858

Specifications:

ASTMB B637/ NACE MR-01-75/HA 46

Incoloy 925 Characteristic

Good mechanical strength and extensive corrosion resistance.

It has good corrosion resistance to chloride ion stress corrosion, local corrosion and various reducing oxidizing chemical media

Incoloy 925 Applications

Construction

Bridges

Petrochemical Industry

Ship Building

Engineering

General Structural Purposes

Offshore and Onshore Services

| Grade | UNS | Density | Tensile Strength (MPa min) | Yield Strength (MPa min) | Reduction of Area min (%) | Elongation min (%) | Hardness (HRC) |

| INCOLOY 925 | N09925 | 8.08 | 965MPa min | 724MPa min | 25% | 18% min | HRC 38 max |

Chemical Composition(%):

| Ni | Cr | Fe | C | Mn | S | Si |

| 42.0-46.0 | 19.5-22.5 | 22min | 0.03max | 1.0max | 0.03max | 0.5max |

| Cu | P | Mo | Nb | Ti | Al | |

| 1.5-3.0 | 0.03max | 2.5-3.5 | 0.5max | 1.9-2.4 | 0.1-0.5 |

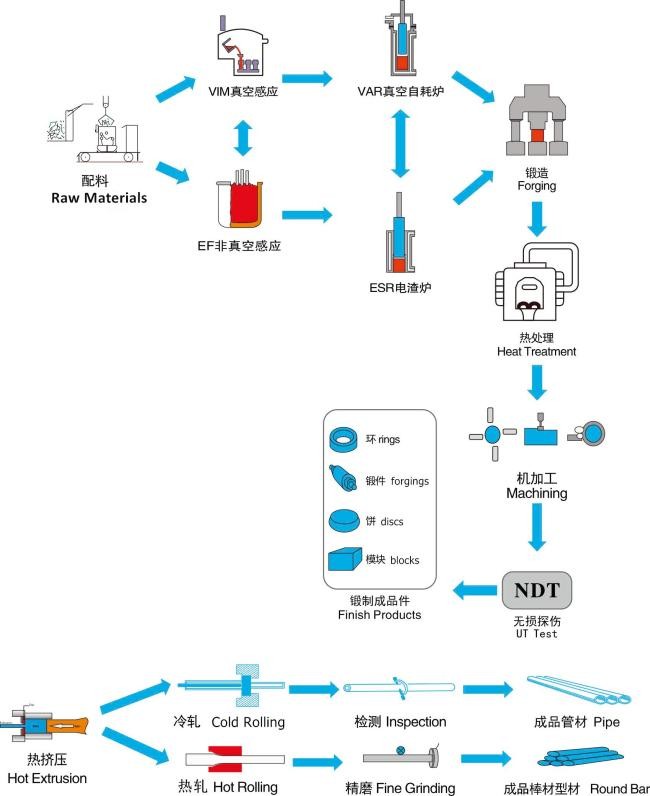

Production Process:

|

|

Incoloy Alloy 925 UNS N09925 Bar With High Tensile Fatigue Strength Images |